App ⟡ Mobile Development

ZARK NI

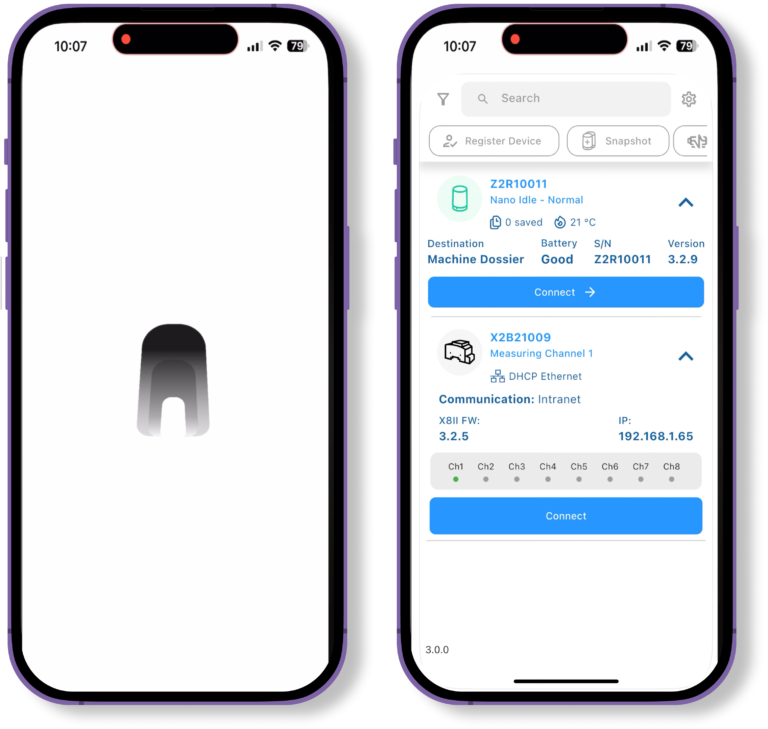

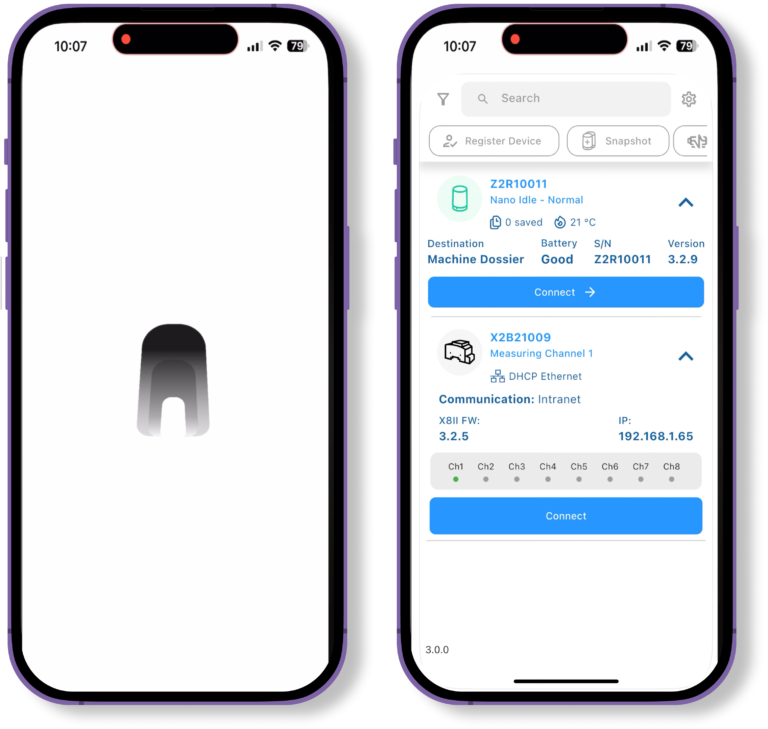

Zark NI is a mobile app built for vibration analysis in large industrial environments, connecting with BLE sensors to help technicians monitor and maintain critical equipment. By analyzing real-time vibration data, it identifies potential issues early, reducing downtime and extending equipment life. Paired with Zark Update, a companion tool for configuring and updating sensors, the system enables fast setup, diagnostics, and adjustments—all from a mobile device. Together, they provide a portable, effective solution for proactive industrial maintenance.

ZARK

Live on the App Store

Overview

Zark NI and Zark Update are purpose-built mobile tools that bring clarity and efficiency to industrial maintenance. Designed for use in large factories, they connect seamlessly with BLE vibration sensors to help teams monitor equipment health, catch early warning signs, and avoid costly downtime. With a clean, intuitive interface and a focus on real-time analysis and configuration, the apps simplify complex processes and deliver immediate value to on-site technicians and reliability engineers.

Project Goals

At Mirastart, our goal with Zark NI and Zark Update was to build a modern, mobile-first solution that helps factory teams monitor and maintain equipment with greater speed, accuracy, and convenience. We set out to replace outdated, complex systems with intuitive tools that connect directly to BLE vibration sensors—giving users real-time insights into machine performance right from their mobile devices.

We developed Zark NI to provide accessible, on-the-go vibration analysis, while Zark Update was designed to give teams full control over sensor configuration and firmware updates. Together, these tools support predictive maintenance workflows, reduce unexpected downtime, and make critical diagnostics easier for technicians, engineers, and maintenance managers across large industrial environments.

Key Features & Functionality

Challenges & Solutions

Challenge 1: Reliable Communication with BLE Sensors in Industrial Environments

Challenge 2: Presenting Complex Vibration Data on a Mobile Interface

Challenge 3: Remote Sensor Configuration and Firmware Updates

Our Work

At Mirastart, we partnered with the Zark team to design and engineer a mobile-first solution that brings real-time vibration monitoring and sensor configuration into the hands of industrial maintenance teams. Our focus was on delivering a clean, reliable experience that simplifies complex diagnostics and enhances operational efficiency on the factory floor.

Discovery & Strategy

We started by understanding the real-world challenges faced by factory technicians and maintenance engineers. Our discovery process included identifying gaps in existing vibration monitoring workflows and understanding the technical constraints of BLE sensor integration. By mapping out the user journey and aligning it with sensor hardware capabilities, we defined a focused strategy to deliver a practical, mobile-first solution. This laid the foundation for a product that would not only meet functional requirements but also support seamless adoption in high-pressure industrial environments.

UI/UX Design

Our design approach centered on clarity, speed, and usability. We created a mobile-first interface that simplifies the presentation of complex vibration data like FFTs and time waveforms. Visual feedback, clear iconography, and technician-friendly flows were key in making the tools intuitive for both experienced engineers and new users. The result is a lightweight yet powerful experience that minimizes friction while maximizing operational insight, even in fast-paced or low-connectivity environments.

Development & Engineering

We engineered both Zark NI and Zark Update to deliver reliable BLE communication, secure data transfer, and real-time performance in challenging factory settings. The mobile applications were built using scalable frameworks and optimized for low-latency interactions with BLE sensors. Zark NI was focused on live monitoring and analysis, while Zark Update handled remote sensor configuration and firmware management. Our backend solutions supported efficient data handling, modular growth, and seamless syncing across devices.

Testing & Optimization

To ensure the apps could withstand real-world use, we performed rigorous testing across a range of industrial conditions and device types. This included BLE stress testing, usability feedback from field technicians, and performance checks under limited network conditions. We optimized the user interface for clarity and responsiveness, and validated that sensor communication remained stable even in signal-heavy environments. Feedback from test sessions directly influenced refinements in both functionality and flow.

Launch & Deployment

With both Zark NI and Zark Update ready for release, we focused on delivering a smooth and strategic deployment. We prepared App Store listings, coordinated version control, and ensured compliance with platform guidelines. A phased rollout approach was used to monitor early user feedback, address edge cases, and ensure system stability under real-world conditions. Support resources, including onboarding guides and internal documentation, were developed to assist factory teams with adoption. By combining technical readiness with thoughtful user enablement, we set the foundation for a successful launch and ongoing growth across industrial environments.

Business Outcomes

Zark NI and Zark Update have introduced a practical, mobile-first solution that transforms how industrial teams monitor and maintain factory equipment. By replacing outdated hardware and manual workflows with real-time vibration analysis and wireless sensor configuration, the platform improves operational efficiency, reduces unplanned downtime, and supports predictive maintenance strategies at scale.

Improved Equipment Monitoring Accuracy

Factory teams now have access to consistent, real-time insights into equipment health, allowing them to detect issues early and take action before failures occur. The integration of BLE sensors with mobile analysis tools has significantly enhanced the reliability of vibration diagnostics.

Reduced Maintenance Time & Manual Effort

Mobile-based tools eliminate the need for bulky hardware or desktop software, enabling technicians to complete diagnostics and sensor configurations directly on the factory floor. This has led to faster maintenance cycles and fewer interruptions in production.

Increased Operational Uptime

By enabling proactive maintenance through early fault detection, the platform helps factories minimize unexpected downtime. This contributes to smoother operations, longer equipment lifespan, and reduced emergency repair costs.

Streamlined Sensor Management Across Facilities

With Zark Update, managing large fleets of BLE sensors is faster and more efficient. Technicians can update firmware, modify settings, and resolve issues without taking sensors offline, improving consistency and scalability across industrial sites.

Positioned for Scalable Growth & Integration

The success of the initial deployment creates opportunities for integration with broader factory systems, including SCADA platforms, ERP software, and industrial analytics dashboards. The modular architecture supports expansion into more advanced condition monitoring, asset tracking, and enterprise-level reporting.

Let us help you with your business challenges

Contact us to schedule a call or set up a meeting